How Come There Are Sometimes Small Holes on Surface of AlSiC Products

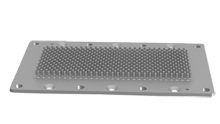

Normal surface of an AlSiC product is covered with a thin layer of Aluminum, we call it aluminum rich skin. This layer is the extent of the matrix Al of AlSiC, used to strengthen solder and consolidate air-tightness. The small holes on this layer are actually the exposed ceramic particles that are not cover by Al. When the small hole problem become widespread, it is always the indication of the poor wetting pretreatment of the ceramic. Other reasons coming from traditional cast defects include stomata dispersed shrinkage, shrinkage cavity, sonim and slag inclusion, the ways to deal with are also traditional.

AlSiC products are some kind of cast produced, only that its casting environment is much worse than conventional precision casting. To get rid of surface small holes completely is impossible even in traditional casting. The large amount of small holes gather and form shades on surface does affect the quality. Good AlSiC products, its surface should be covered with continuous and integrated Al layer when observed by microscope. Small holes look like karst cave. When plenty karst caves converge, it is quality defect.

Fadi Technology has an effective support process to address small hole problem, the surface quality meets with the aerospace cast aluminum criteria and is comparable to that of American and Japan products'.